Mar 29, 2024

Designing a dryer with an axial flow fan and a heat exchanger involves several steps to ensure efficient drying while maximizing heat transfer. Here's a general guide to designing such a system:

Determine Drying Requirements: Understand the drying requirements for the material you intend to dry, including the required drying temperature, moisture removal rate, and airflow rate.

Select Heat Source: Choose a suitable heat source for the dryer. This could be steam, hot air, or electric heaters, depending on availability, cost, and efficiency considerations.

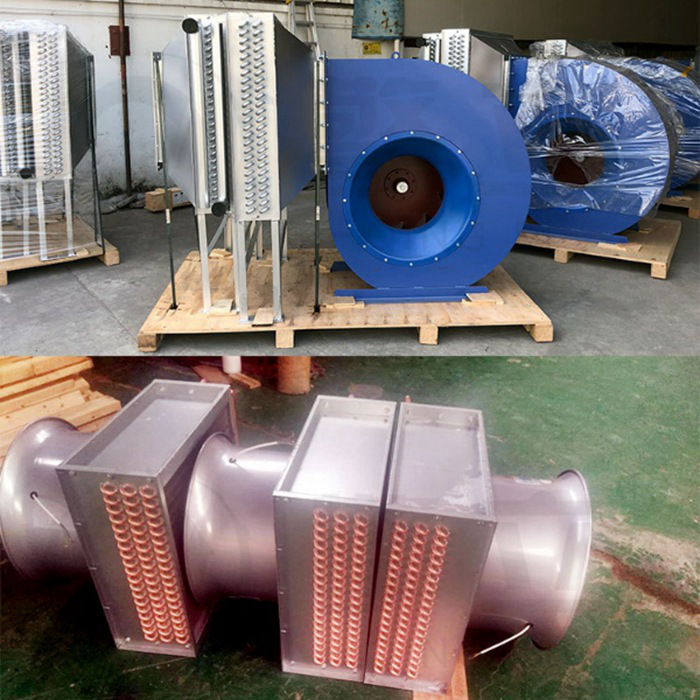

Design the Heat Exchanger: Select a type of heat exchanger that suits your application. Fin tube heat exchangers are commonly used. Determine the size, material, and configuration of the heat exchanger based on the heat transfer requirements and available space.

Integrate the Heat Exchanger with the Dryer: Position the heat exchanger within the dryer system such that the airflow from the axial fan passes through it. Ensure proper sealing to prevent air leakage and maximize heat transfer efficiency.

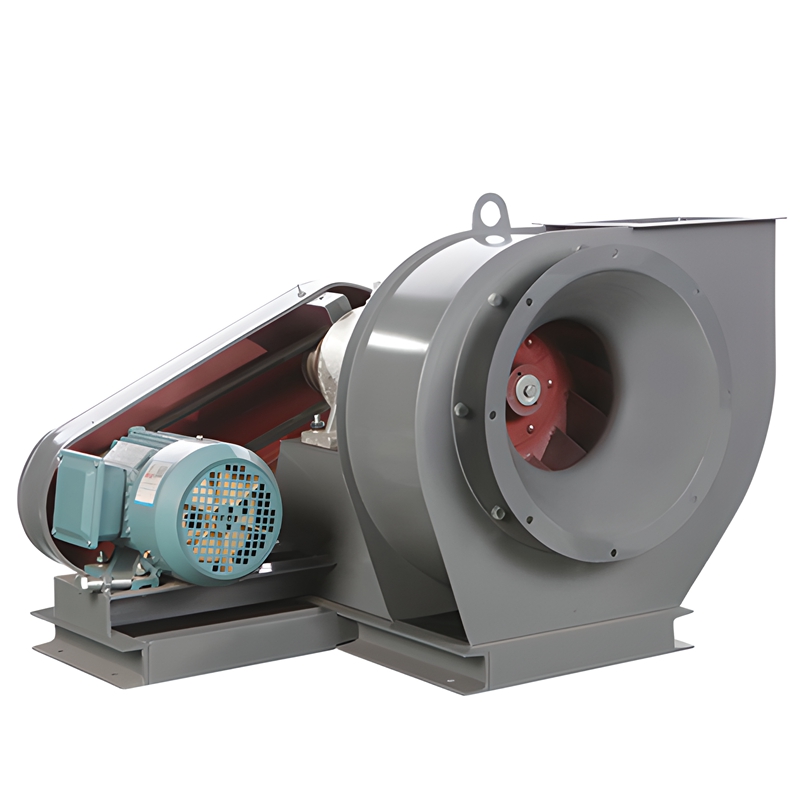

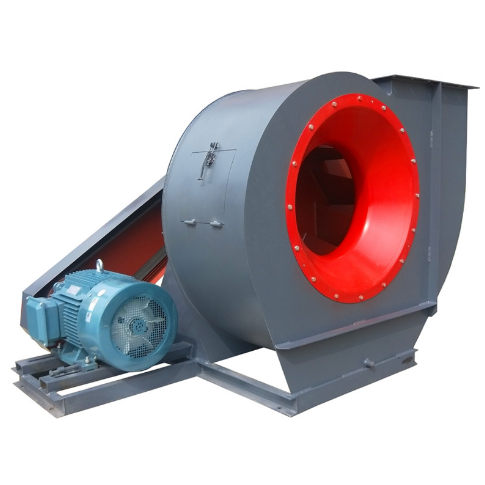

Choose an Axial Fan: Select an axial fan suitable for the airflow requirements of the dryer. Consider factors such as airflow rate, pressure requirements, and energy efficiency. Position the fan to ensure uniform air distribution throughout the dryer.

Design the Dryer Chamber: Design the dryer chamber to accommodate the material to be dried and facilitate efficient airflow. Consider factors such as chamber size, insulation, air inlet/outlet placement, and material handling mechanisms.

Control System Design: Develop a control system to regulate the operation of the fan, heat source, and other components of the dryer. Incorporate temperature and moisture sensors to monitor drying conditions and adjust parameters as needed.

Safety Measures: Implement safety features such as temperature and pressure alarms, emergency stop buttons, and ventilation systems to ensure safe operation of the dryer.

Testing and Optimization: Conduct tests to evaluate the performance of the dryer system, including heat transfer efficiency, drying time, and energy consumption. Make adjustments as necessary to optimize performance and meet drying requirements.

Maintenance Plan: Develop a maintenance plan to ensure the long-term reliability and efficiency of the dryer system. This includes regular inspection, cleaning, and servicing of components such as the fan, heat exchanger, and control system.

By following these steps and considering the specific requirements of your application, you can design a dryer with an axial fan and heat exchanger that effectively removes moisture from the material while minimizing energy consumption and ensuring safe operation.

Yjventilationfan is professional heat exchanger manufacturer, we can supply best heat exchangers according your needs.