Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

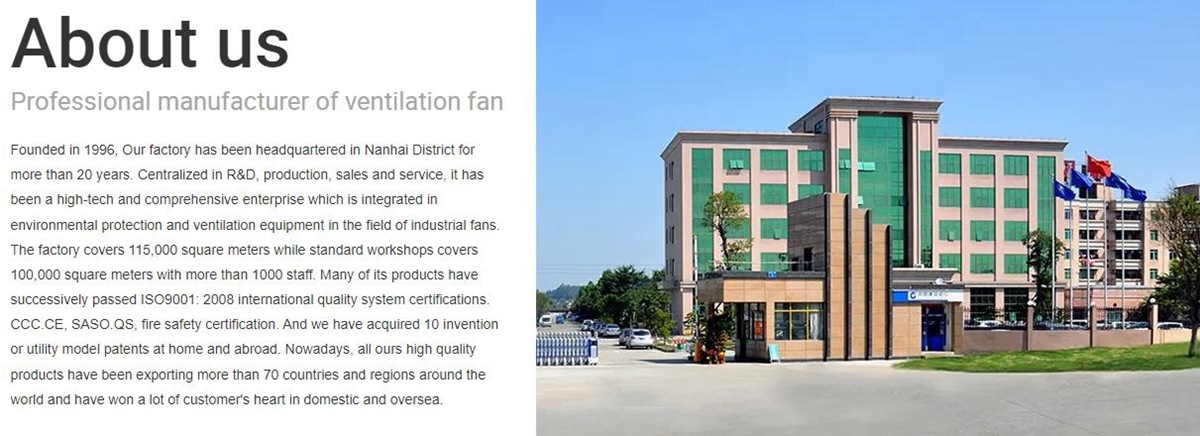

Founded in 1996, Our factory has been headquartered in Nanhai District for more than 20 years. Centralized in R&D, production, sales and service, it has been a high-tech and comprehensive enterprise which is integrated in environmental protection and ventilation equipment in the field of industrial fans.

The factory covers 115,000 square meters while standard workshops covers 100,000 square meters with more than 1000 staff. Many of its products have successively passed ISO9001: 2008 international quality system certifications. CCC.CE, SASO.QS, fire safety certification. And we have acquired 10 invention or utility model patents at home and abroad. We also specializes in Misting Fan, Ventilation Fan, and Fresh Air system production. Nowadays, all ours high quality products have been exporting more than 70 countries and regions around the world and have won a lot of customer's heart in domestic and oversea.

Professional Products:

1. We offer a range of professional products, including centrifugal fans, axial fans, duct fans, fan impellers, and mist fans.

2. We accommodate non-standard units and small orders.

3. Our accessories include forward impellers, backward impellers, axial impellers, and atomizers.

4. We specialize in ventilation and cooling solutions for industrial and commercial buildings.

Professional Manufacturing:

1. Our team of experienced engineers and R&D professionals supports product technology and development.

2. We have advanced manufacturing and inspection equipment, including laser cutting, CNC, dynamic balance, and product testing center.

3. Every product undergoes thorough inspection before delivery.

Professional Service:

1. Our products are exported to over 50 countries.

2. We prioritize on-time delivery.

3. All product have 3 years warranty.

4. Our experienced customer service team excels in communication, answering questions, and resolving issues.

years export experience

factory square meter

staffs

Ventilation system design service is fast becoming a valuable resource for our customers.

The ventilation fan design service follows a systematic process to ensure the creation of an effective and efficient fan system tailored to the specific requirements of the client. Here is an overview of the steps involved in the ventilation fan design process:

1. Requirement Analysis: The design process begins with a thorough analysis of the client's ventilation needs and requirements. This includes understanding the application, space dimensions, airflow rates, pressure requirements, environmental factors, and any specific constraints or challenges.

2. System Assessment: The ventilation system in which the fan will be installed is evaluated. Factors such as existing ductwork, airflow pathways, and potential bottlenecks are assessed to determine the most suitable fan configuration and placement.

3. Design Conceptualization: Based on the requirements and assessment, a design concept is developed. This involves selecting the appropriate fan type (such as axial or centrifugal), determining the fan size, and considering factors like noise control, energy efficiency, and maintenance requirements.

4. Fan Selection: The design team identifies potential fan models from reputable manufacturers that align with the project specifications. Factors considered during the selection process include fan performance curves, efficiency ratings, durability, and compatibility with the desired control systems.

5. Performance Modeling: Using computer-aided design (CAD) software or specialized fan selection tools, the design team models the performance characteristics of the selected fan options. This allows for accurate predictions of airflow patterns, pressure drops, and other critical parameters within the ventilation system.

6. Detailed Engineering: Once a specific fan model is chosen, detailed engineering is conducted. This involves creating comprehensive drawings and specifications that outline the fan's dimensions, materials, electrical requirements, and any necessary mounting or structural considerations.

7. Prototyping and Testing: In some cases, a prototype of the fan system may be constructed for testing and validation purposes. This ensures that the fan performs as intended and meets the specified requirements for airflow, noise levels, and efficiency.

8. Manufacturing and Installation: After the design and testing phases are complete, the approved fan design moves into the manufacturing stage. The fan components are fabricated, assembled, and quality-tested before being prepared for installation. The installation process may involve working closely with contractors, engineers, or on-site technicians to ensure proper integration into the ventilation system.

9. Performance Monitoring: Once the fan system is operational, ongoing performance monitoring and maintenance are essential. Regular inspections, data collection, and adjustments help optimize fan performance, ensure long-term reliability, and identify any potential issues that may arise.

Throughout the ventilation fan design process. This ensures that the final fan system meets the client's requirements, operates efficiently, and contributes to a well-ventilated and comfortable environment.

Our team of technical engineers are experts in their field so your enquiry will always be handled by an experienced person who understands your application. Our business is split into two specialist departments.

Hi! Click one of our members below to chat on